Mechanical Projects

Cam-Follower Mechanism

Designed a high-cycle cam-follower system using SolidWorks and MATLAB. Analyzed motion profiles with SVAJ plots and implemented a modified trapezoidal cam for smooth acceleration. CNC-milled the cam and verified 6 mm displacement over 1 million cycles.

Space Capsule Project

The following slides showcase the capsule assembly and manufacturing process, including CAD structure, simulations, and some of the fabrication process.

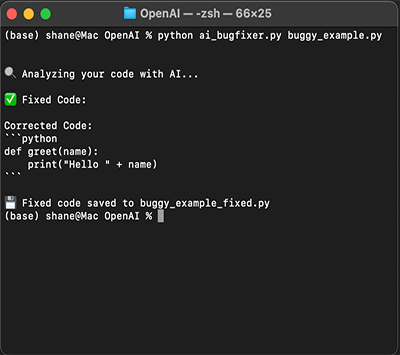

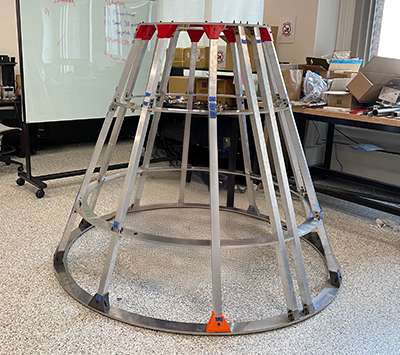

This image shows the labeled capsule frame used in the motion simulator project. The structure includes four 5052 aluminum bulkhead rings, connected by 6061 aluminum stringers for structural support. The outer rings are joined using custom Nylon 12 brackets, 3D printed in-house, while the inner connections are reinforced with CNC-routed sheet metal brackets. To allow transport via elevator, each ring was split in half and reassembled using 6061 aluminum connection plates. Two female connectors are mounted on each side of the capsule, designed to receive a male axle, enabling one degree of freedom pitch rotation.

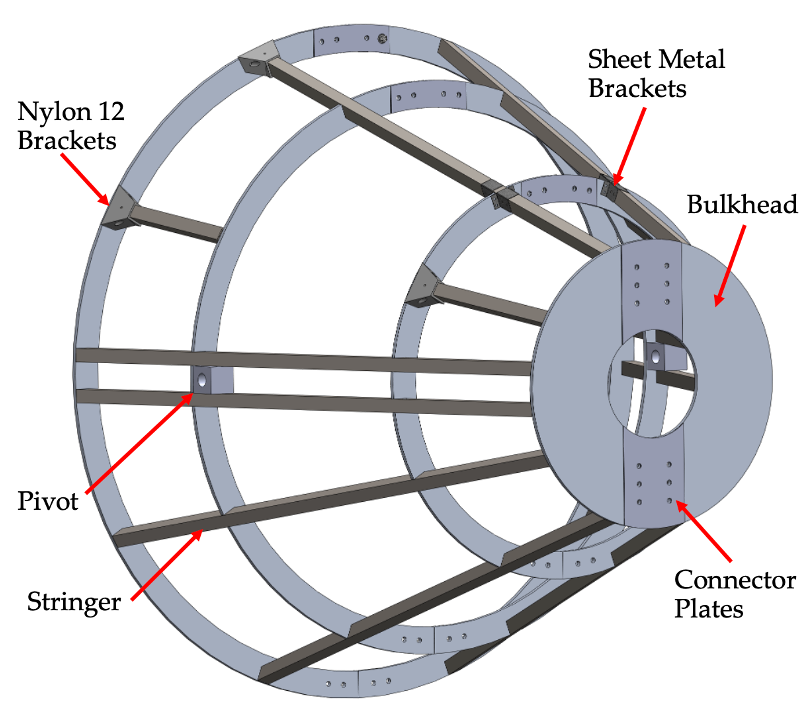

The next image shows a diagram of the system dynamics, including the center of gravity (COG), center of rotation (COR), and distributed weight loads. This helped define mechanical requirements and guided torque and bearing selection.

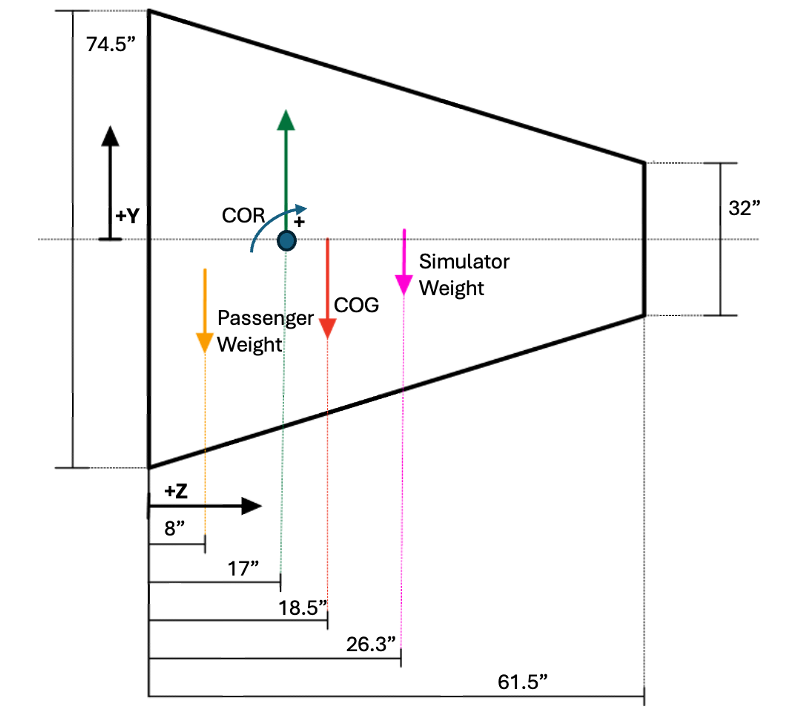

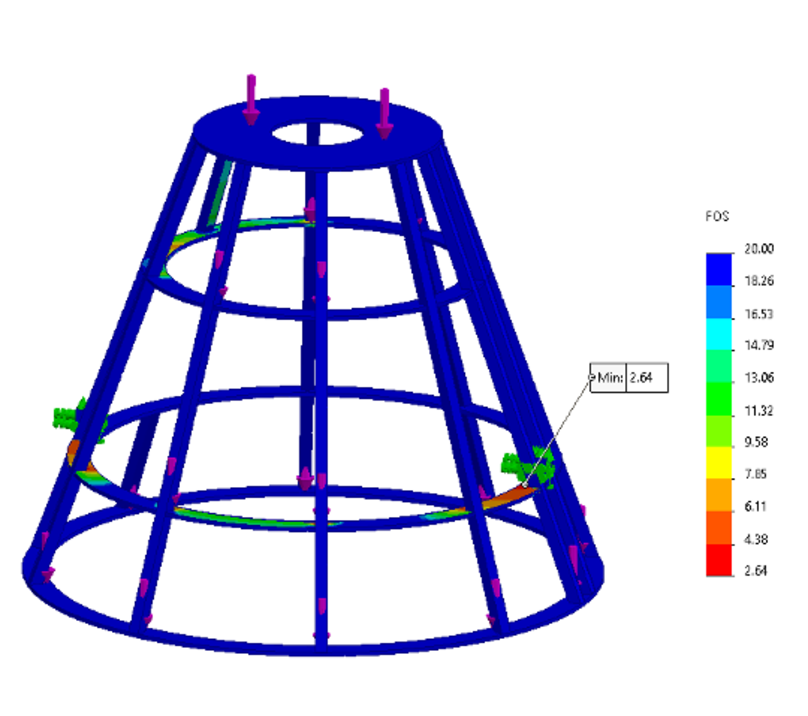

The following slides display SolidWorks simulations under both horizontal and vertical loading conditions. Both scenarios yielded a Factor of Safety (FoS) above 2, validating the structural design.

The first image shows the bulkhead rings being cut by our sponsor, Waste Gas Fabricating, using a water jet. All four rings were machined from aluminum plate.

The second image shows a CNC router cutting connection plates, which were also used to fabricate the sheet metal brackets that attach to the inner rings.

A custom jig was developed to keep the rings concentric and evenly spaced during assembly, which was critical to maintain dimensional accuracy.

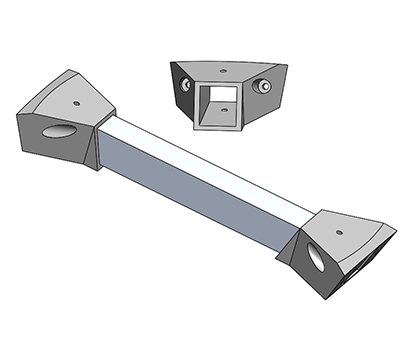

The next image shows the custom Nylon 12 bracket I designed in SolidWorks, which connects the outer stringers to the bulkhead frame.

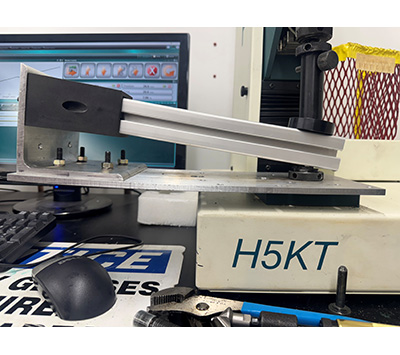

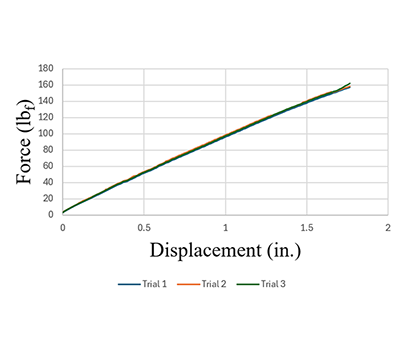

A bending test was performed on the 3D printed brackets to determine their maximum load before fracture.

The test data was captured and plotted as a force vs. displacement curve to quantify structural performance.

The female connector block, shown next, was milled using a CNC machine to accept the rotating axle interface.

The final image shows the fully assembled capsule. A future team will design and build the cradle system to support the capsule for pitch testing.

Robotics Projects

-

Quadruped Line Following Robot Using ROS 2

Built an autonomous quadruped robot using ROS 2 and Python, powered by a Raspberry Pi camera. The robot followed a line and was programmed to stop at blue and green markers to perform short dance routines before continuing. It came to a full stop at the red marker at the end of the track. To enable peer-to-peer DDS communication despite network restrictions, I set up a Husarnet VPN. This project earned 2nd place in the MiniPupper Competition at the IEEE Region 1 and 2 Student Conference in 2025.

Hardware Projects

-

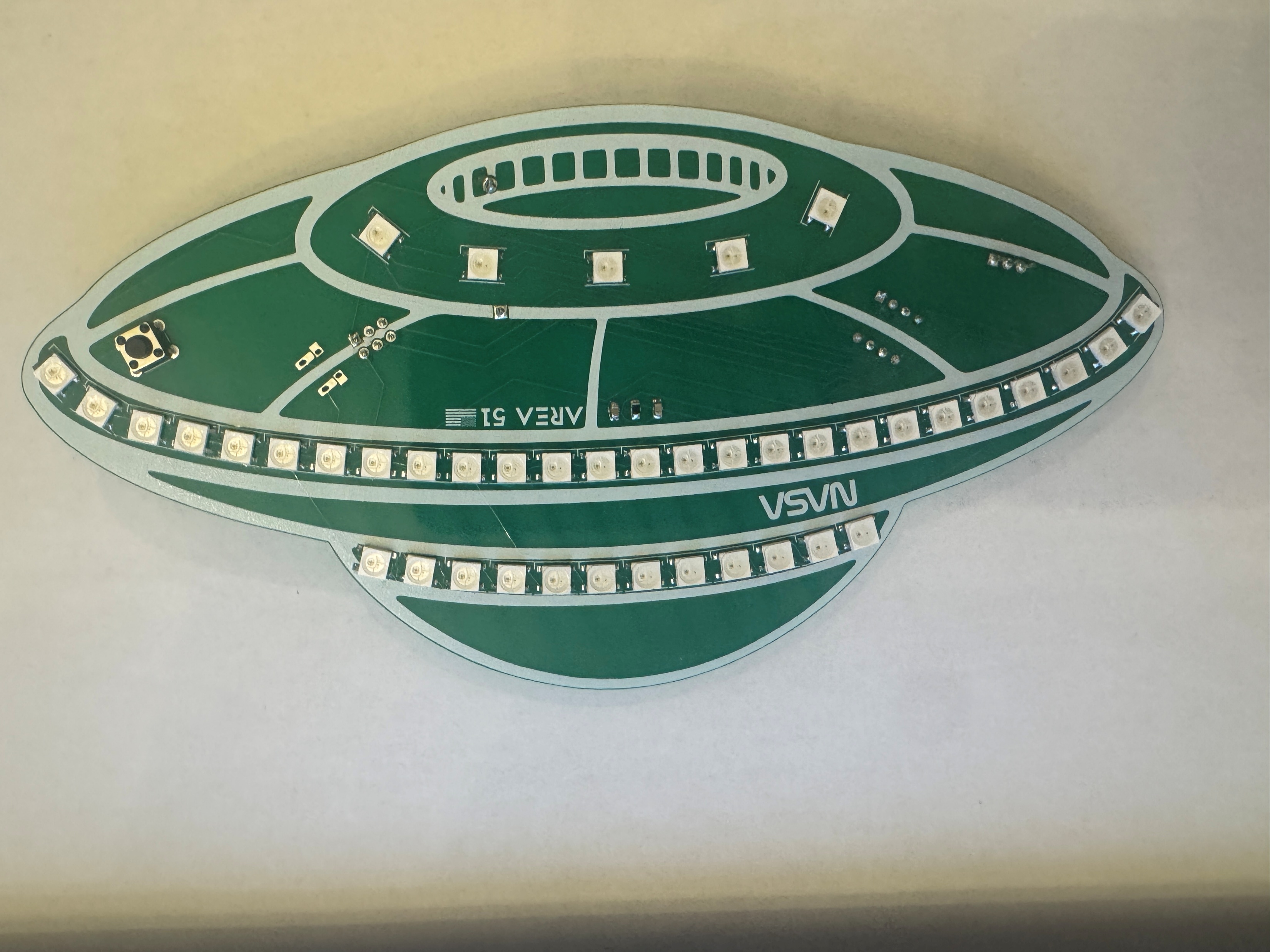

UFO PCB Board

Designed a UFO-shaped custom PCB in KiCad with NeoPixels. I hand-soldered the through-hole components and used solder paste with a reflow oven for the surface-mount parts. The board was both functional and fun, with colorful lighting animations that brought the design to life during demos.

Software Projects

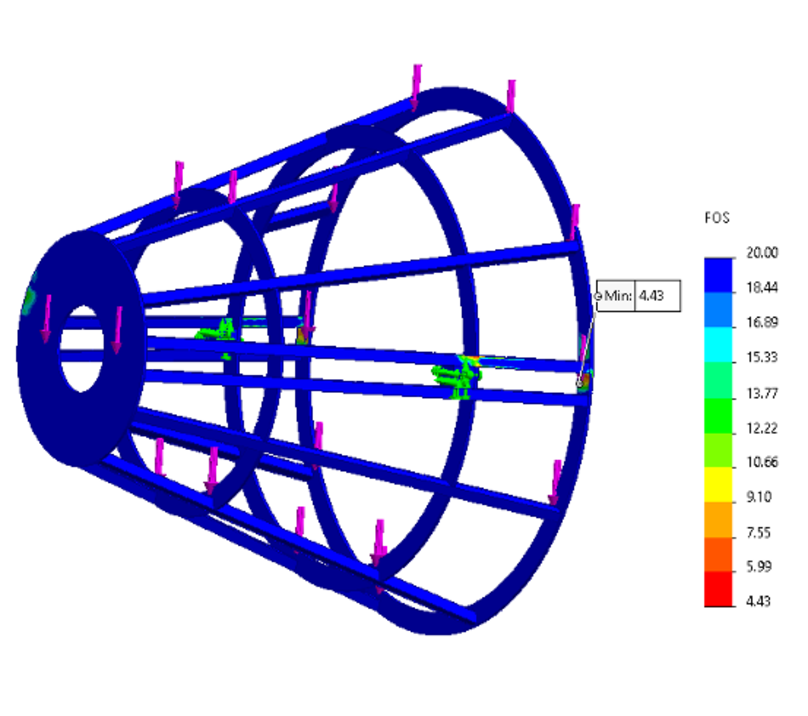

AI-Powered Python Bug Fixer (OpenAI CLI Tool)

This project is a command-line tool I built in Python that automatically fixes buggy code using OpenAI's GPT API.

The tool reads a `.py` file, sends it to ChatGPT with a carefully structured prompt, and writes the corrected version

to a new file. It also displays the fixed code in the terminal. I used the openai Python package (v1.0+)

and followed a modular design pattern with environment variable security and error handling. This tool demonstrates

my ability to integrate LLM APIs with real developer workflows.